In the plastics industry, material mixer machines, also known as plastics blender machines, are used to mix and blend plastic materials and additives together.

These machines are often used in the production of plastic products to ensure that the materials are thoroughly mixed and the final product has a consistent composition.

There are several different types of material mixer machines used in the plastics industry, including horizontal mixers, vertical mixers, and conical mixers.

What is plastics industry mixing process?

The mixing process in the plastics industry is the process of blending together plastic materials and additives in a material mixer machine to produce a homogeneous mixture. Can consistent quality the final mixed plastics. The mixture is then used in the production of plastic products.

The mixing process is an important step in the plastics production process as it ensures that the materials are thoroughly blended together and the final product has a consistent composition.

In general, the plastics industry mixing process involves the following steps:

- Preparation: The plastic materials and additives are prepared for mixing by grinding them into small particles and ensuring that they are dry and free of contaminants.

- Charging: The prepared materials are fed into the mixing chamber of the material mixer machine through a hopper.

- Mixing: The mixing shaft of the mixer rotates and blends the materials together, using a series of blades or paddles to mix the materials thoroughly.

- Discharging: Once the mixing is complete, the mixed materials are discharged from the mixing chamber through a discharge port.

- Quality control: The mixed materials are typically checked for quality and consistency before being used in the production of plastic products.

The specific details of mixing process may vary depending on the type of mixer machine being used, the type of plastic materials and additives being mixed, and the desired properties of the final product.

What is horizontal mixer machine?

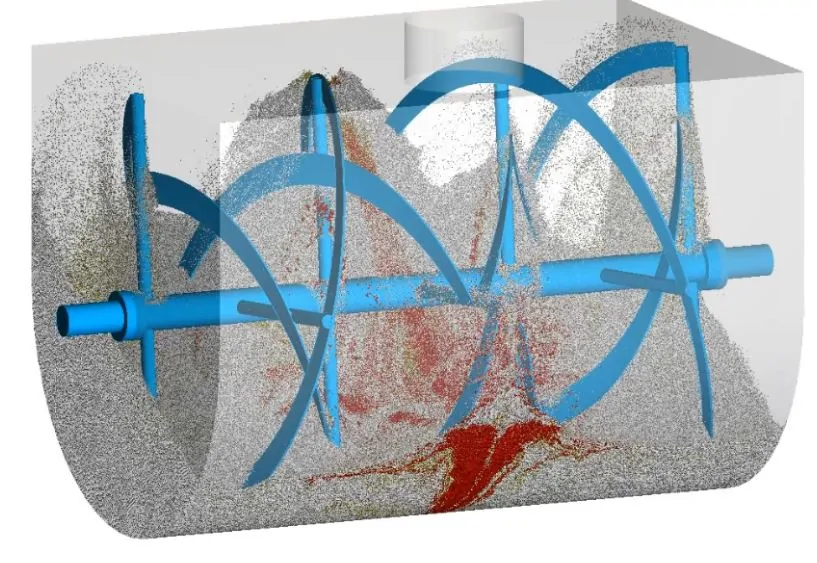

A horizontal mixer machine is a type of material mixing equipment used in the plastics industry to mix and blend plastic materials and additives together.

As the name suggests, these machines have a horizontal orientation, with a horizontal mixing shaft and a series of blades or paddles attached to the shaft.

Horizontal mixer can be used in many industries, plastic, food can be mixed powder materials, and the mixing degree is also very high.

What are the horizontal mixer parts?

- Mixing chamber: This is the main body of the mixer where the materials are blended together.

- Mixing shaft: This is a horizontal shaft that rotates within the mixing chamber and is equipped with a series of blades or paddles. The mixing shaft is powered by a motor and is responsible for blending the materials together.

- Discharge port: This is an opening at the bottom of the mixing chamber where the mixed materials are discharged from the mixer.

- Drive system: This consists of a motor, gears, and other components that provide the power to rotate the mixing shaft.

- Support structure: This is the frame or chassis of the mixer that supports the other components and provides stability to the machine.

- Control panel: This is the panel where the operator can control the operation of the mixer, including starting and stopping the machine, adjusting the mixing speed, and setting the mixing time.

- Safety guards: These are covers or barriers that protect the operator from the moving parts of the mixer.

Factors affecting the plastic mixing effect of horizontal mixers:

The mixing shaft of a horizontal mixer is typically a horizontal shaft that rotates within the mixing chamber and is equipped with a series of blades or paddles.

The design of the mixing shaft plays a critical role in the mixing efficiency of the machine. Here are some key factors to consider when designing the mixing shaft of a horizontal mixer:

- Blade or paddle shape: The shape of the blades or paddles can affect the mixing efficiency and the final product quality. Common blade shapes include flat blades, curved blades, and spiral blades.

- Blade or paddle spacing: The spacing of the blades or paddles along the mixing shaft can affect the mixing efficiency and the final product quality. Too close of a spacing can lead to poor mixing, while too wide of a spacing can lead to poor blending.

- Blade or paddle orientation: The orientation of the blades or paddles can affect the mixing efficiency and the final product quality. Common blade orientations include perpendicular to the mixing shaft, angled relative to the mixing shaft, and a combination of both.

- Blade or paddle material: The material of the blades or paddles can affect the durability and wear resistance of the mixer. Common materials include steel, stainless steel, and other wear-resistant alloys.

- Mixing speed: The mixing speed of the mixing shaft can affect the mixing efficiency and the final product quality. Higher mixing speeds can lead to better mixing, but can also increase wear on the blades and paddles.

- Mixing time: The mixing time, or the length of time that the materials are mixed in the horizontal mixer, can also affect the mixing efficiency and the final product quality. Longer mixing times can lead to better mixing, but can also increase wear on the blades and paddles.

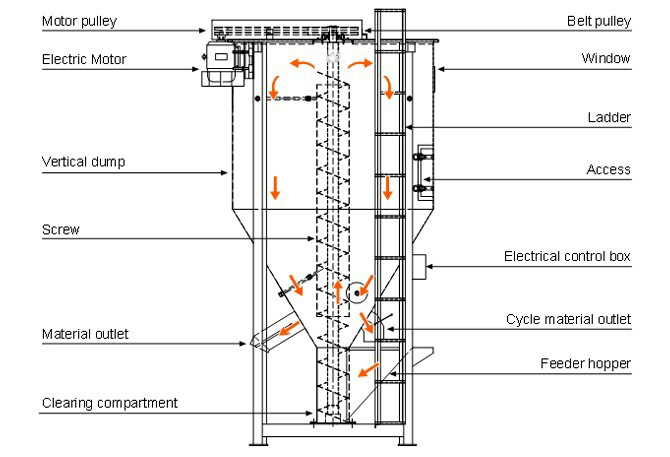

What is vertical mixer machine?

A vertical mixer machine is a type of industrial mixers used in the plastics industry to mix and blend plastic materials and additives together. As the name suggests, these machines have a vertical orientation, with a vertical mixing shaft and a series of blades or paddles attached to the shaft.

The plastic materials and additives are fed into the mixer through a hopper, and the vertical mixing shaft rotates to mix the materials together.

One advantage of vertical mixer machines is that they take up less floor space than horizontal mixers, making them suitable for use in facilities with limited space. Most suitable for mixing granular materials, the price is cheaper than horizontal mixers and conical mixers.

They are also relatively easy to clean and maintain, with simple designs and few moving parts.

What are the special features of the vertical mixers?

Here are some special features that may be found on a vertical mixer machine:

- Adjustable mixing speed: Many vertical mixers have adjustable mixing speeds, allowing the operator to control the speed of the mixing shaft to suit the specific mixing needs of the materials being blended.

- Timer: Some vertical mixers have a timer that can be set to automatically stop the mixing process after a certain amount of time, ensuring that the materials are mixed for the optimal length of time.

- Heating or cooling system: Some vertical mixers have a heating or cooling system that can be used to control the temperature of the mixing chamber, significantly shorter drying rates. Which can be useful for certain types of plastic materials that require specific processing temperatures. For example drying plastic resins.

- Vacuum system: Some vertical mixers have a vacuum system that can be used to remove air bubbles from the mixture, which can be important for certain types of plastic products that require a bubble-free final product.

- Automatic discharging system: Some vertical mixers have an automatic discharging system that can be used to automatically discharge the mixed materials from the mixing chamber once the mixing is complete. This can help to streamline the mixing process and reduce labor costs.

- Control panel: Most vertical mixers have a control panel that allows the operator to control the operation of the mixer, including starting and stopping the machine, adjusting the mixing speed, and setting the mixing time.

- Safety guards: Vertical mixers typically have safety guards in place to protect the operator from the moving parts of the mixer.

- Lubrication system: Some vertical mixers have a lubrication system to reduce friction and wear on the moving parts of the mixer.

Guide to the use of vertical mixers

Here are some general guidelines for using a vertical mixer machine:

- Read and understand the operator’s manual: Before using the vertical mixer, make sure to read and understand the operator’s manual. This will provide important information about the safe operation and maintenance of the mixer.

- Wear appropriate personal protective equipment: When using the vertical mixer, make sure to wear appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection.

- Follow proper loading procedures: When loading materials into the vertical mixer, make sure to follow proper loading procedures to ensure the safe and efficient operation of the mixer.

- Set the mixing speed and time: Adjust the plastics mixing speed and time to suit the specific mixing needs of the materials being blended.

- Monitor the mixing process: During the mixing process, monitor the mixer to ensure that it is operating properly and that the raw materials are being mixed properly.

- Stop the mixer before cleaning or maintenance: Before cleaning or performing maintenance on the mixer, make sure to stop the mixer and disconnect it from the power source.

- Follow proper cleaning and maintenance procedures: Follow proper cleaning and maintenance procedures as outlined in the operator’s manual to ensure the long-term performance and safety of the mixer.

- Report any problems or issues: If you encounter any problems or issues with the vertical mixer, make sure to report them to the appropriate personnel for resolution.

What is the conical mixer machine?

A conical mixer machine is a type of material mixer machine used in the plastics industry to mix and blend plastic materials and additives together. These machines are characterized by a conical mixing chamber with a central mixing shaft and a series of blades or paddles attached to the shaft.

The plastic materials and additives are fed into the mixer through a hopper, and the mixing shaft rotates to mix the materials together.

Conical mixer machines are often used for mixing powder to small volumes of materials, and they are suitable for a wide range of plastic materials and additives. They are also commonly used for mixing other types of materials, such as chemicals, food products, and pharmaceuticals.

How the conical mixers work?

The conical mixer machine works by blending together plastic materials and additives in a conical mixing chamber. The mixing chamber is typically in the shape of a cone, with a central mixing shaft and a series of blades or paddles attached to the shaft. The plastic materials and additives are fed into the mixer through a hopper, and the mixing shaft rotates to mix the materials together.

As the mixing shaft rotates, the blades or paddles move the materials around the mixing chamber, blending them together and ensuring a homogeneous mixture.

The conical shape of the mixing chamber helps to promote thorough mixing and prevent the materials from becoming stuck in corners or pockets.

Once the mixing is complete, the mixed materials are typically discharged from the mixer through a discharge port at the bottom of the mixing chamber.

The specific details of the conical mixer machine may vary depending on the specific design and features of the machine.

Top plastic industrial mixers manufacturer in VietNam

Machinery is a leading manufacturer of plastic mixer machines and other plastic processing equipment in VietNam. They offer a range of mixer machines, including horizontal mixers, vertical mixers, and screw mixers.

If you are looking for a manufacturer of mixers for your plastic production line, you can contact VietDai without hesitation.

Their rich mechanical experience accumulated over the years in the plastics industry will allow you to take the easy way out of the process of purchasing a mixer, and produce the mixer you need custom-made with greater efficiency and more specialized industry knowledge.

VietDai Plastic Machinery Co. LTD

Hotline: Mr. Trung: +84-937 470 861 – Mr. Vien: +84-886 547 668 Mr. Ba: +84-969 778 568 - Mr. Dung +84-976 556 525

Email: maynhuavietdai.hd@gmail.com