What You Need is a Plastic Crusher Shredder

Plastic consumption and waste continue to rise globally. Products made of plastic often end up as non-biodegradable trash after being discarded. Plastic shredding machines provide an eco-friendly solution by enabling the recycling of these materials.

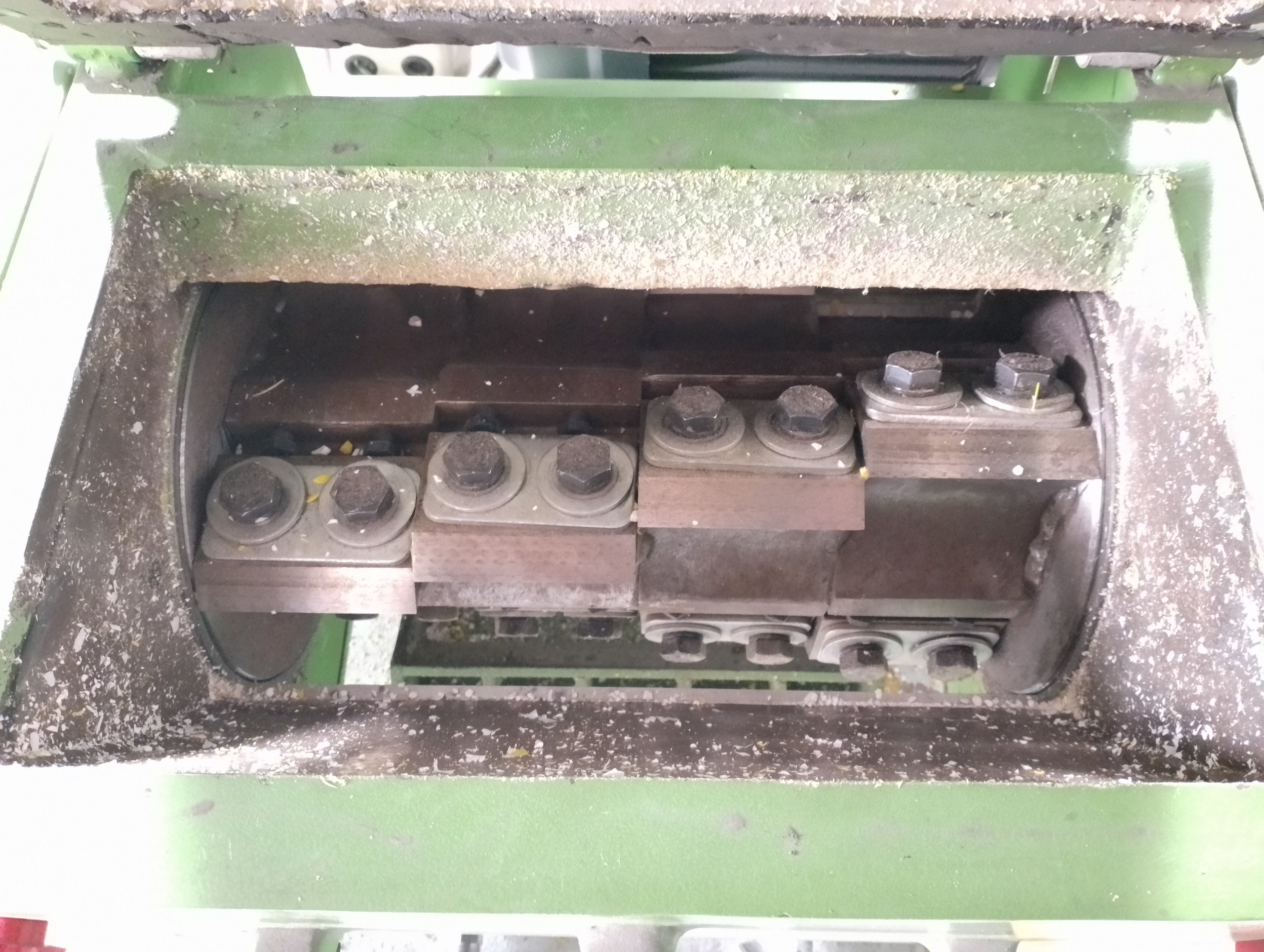

Shredders flexibly process diverse plastic types into recyclable fractions. With customizable rotor designs and specialized cutting tools, they efficiently shred thermoplastics like PE, PP, PVC, PS, PU, and PET, as well as various thermosets and elastomers. These smaller waste plastics can be effectively granulated for reuse.

By supporting closed-loop recycling, plastic shredders reduce the environmental impact of plastic goods. Their ability to fragment bulky plastic waste streamlines size reduction for remanufacturing. Shredders play an integral role in mitigating plastic pollution through sustainable recovery and reprocessing methods.

A plastic crusher, also known as a plastic grinder or plastic granulator, is a machine used in the plastic recycling process. It's designed to break down solid plastic waste efficiently for further processing. Here are some key points about plastic crushers:

1. Function: Plastic crushers are specialized in crushing various kinds of plastic materials into granules of different sizes. Crushed plastics can be recycled for reproduction of plastic products. This machine can help reduce the volume of plastic waste, greatly save costs and resources.

2.Types: There are various types of plastic crushers, such as industrial plastic crushers and shredders, which flexibly process diverse plastic types into recyclable fractions.

3. Working Principle: The motor of the plastic crusher drives moving blade cutter to rotate at high speed. High speed rotating moving blades form a relative movement with fixed blades. Through the clearance between them, big materials will be crushed into small sizes.

4. Manufacturers: Several companies manufacture plastic crushers, including VietDai CO. LTD.

5. Applications: Plastic crushers can crush various kinds of plastics, such as plastic bottles, plastic profiles, plastic pipe, plastic plate, plastic sheet, plastic shells, plastic film, woven bags, etc.

Remember, the choice of a plastic crusher depends on your specific needs, including the type of plastic you're working with, the scale of your operations, and your budget.

How Plastic Shredders Can Help You Recycle Waste Plastics

Plastic shredders are machines that can break various types of plastic waste into smaller pieces for easy recycling. They are also known as plastic crushers or plastic granulators. Plastic shredders play a vital role in plastic recycling plants and production facilities, which process plastic materials used as raw materials or finished products in other industries.

Plastic crushers are available in different models and specifications depending on the type and size of plastic waste to be crushed. They also have different internal mechanisms that allow them to move horizontally, vertically, or rotationally, with varying speeds and torques.

The recycling industry values shredders customized for their specific plastic waste streams. Customized solutions enable efficient size reduction and material recovery, which are essential for economical reprocessing. Continuous innovation and custom engineering can help optimize plastic recycling operations.

VietDai Plastic Machinery Co. LTD

Head office: Thanh Xuan commune, Thanh Ha district, Hai Duong province

Branch: 179 Duong Cai Market, Trung Trac commune, Van Lam district, Hung Yen province

Southern branch: No. 4, Street 10, Kp. Khanh Hoi, Tan Phuoc Khanh Ward, Tx. Tan Uyen, Binh Duong Province.

Hotline: Mr. Trung: +84-937 470 861 – Mr. Vien: +84-886 547 668

Email: maynhuavietdai.hd@gmail.com